Ujo Tsumugi Preservation Society

Representative:

Masako Sumoto

* Entry as a group

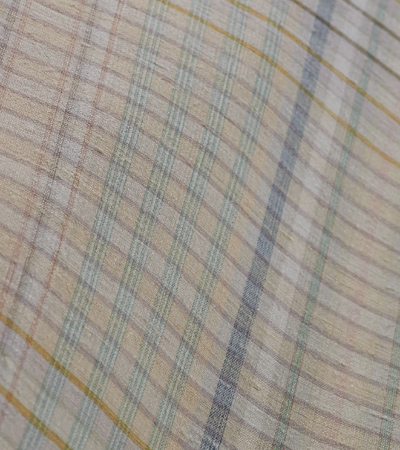

Ujo pongee / Okayama

Matsuzaki Doll Co., Ltd.

Representative:

Mitsumasa Matsuzaki * Entry as a group

Edo Kimekomi dolls / Tokyo

Title of entry

Modern fabric “Kokura Shima Shima” created from traditional Kokura fabric

Special Recognition Award

Title of entry

Modern fabric “Kokura Shima Shima” created from traditional Kokura fabric

Ms. Tsuiki was born in 1952 in Kitakyushu. After leaving the School of Humanities and Social Sciences at Waseda University to take the path of dyeing and weaving, in 1984 she revived and regenerated Kokura fabric for which her hometown has been known for. She has submitted handwoven Kokura fabric Kimono sashes to the Japan Traditional Craft Exhibition and other exhibitions and has received numerous awards. In 2007, she established Kokura Shima Shima as a brand of broadloom machine-woven fabrics and began undertaking its design supervision. She also continues to present her works overseas, such as at Milano Salone.

There had been some 100 Kokura textile production factories at its peak, but the industry began to decline in the early Showa period. Ms. Noriko Tsuiki initially engaged in hand weaving and also outsourced her work to outside factories, but feeling the need to have a proprietary factory, she incorporated her business as Kokura Textile Inc. in 2008.

Taking full advantage of being a small-scale factory, it is increasing its clientele by responding swiftly to even small-lot orders.

The Kokura Shima Shima brand, for which Ms. Tsuiki serves as art director and designer, is being adopted for fashion and interior items and even soccer club uniforms in ways that broaden the possibilities of stripe patterns. “Delicate stripe patterns are given flexibility to widely suit many people” (Ms. Kazuko Todate, head of the jury). Ms. Tsuiki has been recognized for her contribution to revitalizing the production region of Kokura fabric and to developing young talents.

Kokura fabric has a long history that goes back to the early Edo period when it used to be woven by the Kokura clan. The industry declined in the early Showa period, but in 1984, Ms. Noriko Tsuiki brought it back to life by incorporating handweaving techniques and natural dyes. Maximizing the characteristic toughness of the fabric which comes from the high density of its warp yarns and the richness of its colors, she has continuously presented her work, centered mostly on Kimono sashes, at the Japan Traditional Craft Exhibition and other exhibitions. However, each handwoven sash is one of a kind. Therefore, in 2007, she developed the machine-woven broadloom Kokura fabric for general purposes. Taking advantage of its toughness and suppleness, it is being made into fashion items such as bags and new-generation jeans and interior items such as curtains and cloths, and is expanding the possibilities of Kokura fabric to many other sectors.

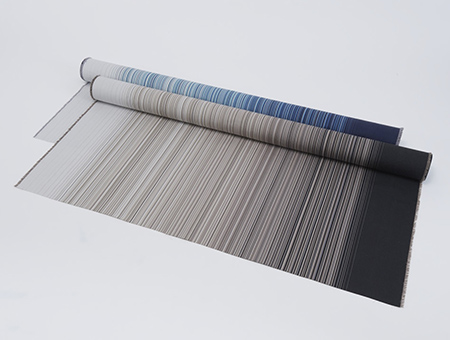

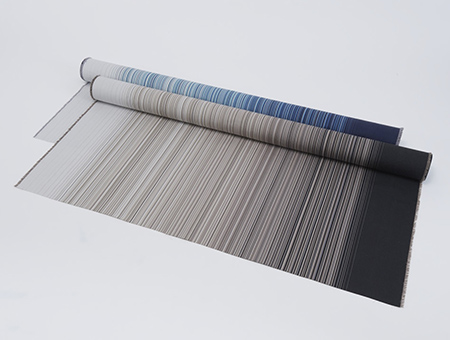

Shima Shima EVOL “Free Monochrome”

The name of the new series of modern Kokura fabric comes from the word “EVOLUTION.” The latest model of warping machine that was introduced to the proprietary factory has enabled 140-cm-wide cloths to be freely designed as though they were a canvas. By merging handcrafting techniques to machine weaving, the high density of warp yarns characteristic of Kokura fabric produces a new depth of expression.

Title of entry

Reproduction, development and preservation of the technique for crafting gold, silver, and copper metal with woodgrain patterns

Special Recognition Award

Akita

Bikou Hayashi

Gold, silver, and copper metal with woodgrain patterns

Title of entry

Reproduction, development and preservation of the technique for crafting gold, silver, and copper metal with woodgrain patterns

Mr. Hayashi was born in 1937 in Akita City, Akita. He entered the craft world at the age of ten and apprenticed with his father. While engaging in metalcraft as an occupation, he also committed himself to reproducing the once lost technique of crafting gold, silver, and copper metal items with wood grain patterns, and worked to establish, develop, preserve, protect, and develop successors of the technique. Mr. Hayashi has served as chairman of Akita Prefecture Arts and Crafts Association (42 years), for which he has received the Akita Municipal Culture Award. He has also been awarded the Akita Prefecture Cultural Achievement Award and a Commendation from the Minister of Education, Science and Culture for Distinguished Service in Local Culture. He is a full member of Japan Kogei Association.

In addition to woodgrain patterns, Mr. Bikou Hayashi has also succeeded in applying cross-grain patterns to metal. Giving diversity to his designs, he produces modern tea utensils, flower vases, decorative boxes, and so on. His works have garnered high praise from the jury members: “When considering the difficult challenge of producing woodgrain patterns, Mr. Hayashi’s intricate skill in freely designing such patterns is remarkable and deserving of recognition” (Mr. Masumi Shimizu, jury member), “Mr. Hayashi’s unwavering belief has shed light on a once lost technique” (Mr. So-oku Sen, jury member).

The tradition of crafting of gold, silver, copper metal with woodgrain patterns originated in the Satake family of the Akita clan, which rose to fame for its gold and silverwork in erstwhile times when mines had flourished in Akita. Several different types of metal, such as gold, silver, copper, and red copper are layered over each other, melded at a high temperature, and repeatedly chiseled and hammered. The resulting plate-like material exhibiting a beautiful woodgrain pattern is called Mokumegane. This craft was said to be founded by Shoami Denbei, a metal craftsman in the employ of the Akita clan, and was adopted for sword guards and hafts. Metalworking of gold and silver is challenging, as gold and silver have differing melting points, and because of the specialness of using precious gold, the technique was kept and handed down in the family through oral tradition without written references whatsoever. Thus, it was long regarded as a fabled technique that cannot be reenacted. Mr. Bikou Hayashi, who entered the path of metalworking at the age of ten, encountered a gold, silver, and copper Mokumegane work that had become a rare item by then when he was in his twenties, and thereafter endeavored to reproduce it. Finally, after entering his sixties, he uncovered Shoami Denbei’s technique and devoted himself to producing works that compare favorably to works that were made before the technique had been lost.

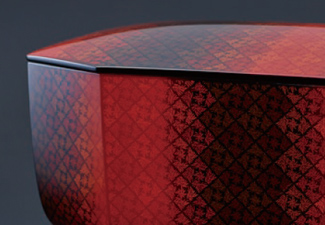

Mosaic box of gold, silver, and copper metal with a woodgrain pattern “Gyokusui”

The beautiful woodgrain pattern on gold, silver and copper metal is highlighted against a black background (red copper) using a mosaic technique. The diversity and profound beauty of Mokumegane is exhibited by adding a delicate cross-grain pattern to the main pattern of stately circular woodgrains.

Tokyo

Creative Sherpa

Representative: Junko Hanezuka and Kohei Fujita * Entry as a group / Edo-style Tokyo Chidori fan

Title of entry

The technique of a craftsman lacking a successor has been inherited by a brilliant disabled youth

Title of entry

Kagawa’s possibilities and attractions are epitomized to the fullest. Development of novel Kagawa lacquerware with stone-powder coating.

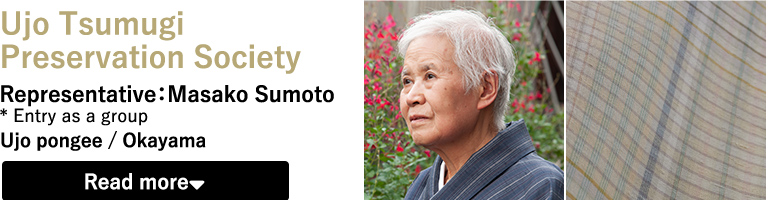

Ujo Tsumugi Preservation Society Representative:Masako Sumoto * Entry as a group Ujo Tsumugi pongee / Okayama

Title of entry

Aiming to keep alive the tradition and technique of Ujo Tsumugi, a designated local traditional craft of Okayama

In 1988, the “Society to Protect Ujo Tsumugi” (now Ujo Tsumugi Preservation Society) was launched mainly by members who studied the basics of Ujo pongee in a three-year study course. In 2009, the society established its base in Ujo Tsumugi Craft Museum. Under fourth-generation master weaver Ms. Masako Sumoto, more than fifty members hone their skills and engage in activities to hand down the tradition to later generations.

The activities that have been launched under the leadership of Ms. Masako Sumoto to preserve and hand down the Ujo Tsumugi technique to later generations have expanded significantly. Among people who have attended her workshop course, there have even been some whose work has been selected for display at a prefectural exhibition. Ms. Sumoto and members of the preservation society have actively participated in various events, studying responses to products and preferred designs and engaging in marketing activities. Such continuous efforts by Ms. Sumoto and the preservation society have earned them the 4th Golden Takumi Award following their finalist status in the 3rd award. “Ms. Sumoto fulfills a large role in solidifying women’s active role in the world of traditional crafts” (Mr. Buzan Fukushima, jury member). The Ujo Tsumugi fabric itself has also received high praise: “The soft feel of the pongee and the extremely delicate nuance of the stripes are magnificent” (Ms. Kazuko Todate, head of the jury).

Ujo Tsumugi is a designated local traditional craft of Okayama. It is produced in a small region, and the entire process, from spinning, refining, and dyeing the yarn, to warping, preparing the loom, and weaving, is done alone without any division of labor. Thus, transmitting the technique is not easy. However, as fourth-generation master weaver, Ms. Masako Sumoto has preserved the technique all by herself and has launched a three-year workshop course to hand down the technique to later generations. Students of the ninth course are now in their final year, and the number of applicants for the tenth course is about to exceed the quota.

Members who learned the basics of Ujo Tsumugi in the workshop course organized Ujo Tsumugi Preservation Society in their desire to hone their skills. They also established Ujo Tsumugi Denshokan as a joint workshop with Ms. Sumoto, where more than fifty members now engage in activities to hand down the tradition and enhance their skills. In 2003, the trademark “Karami Ujo” was registered to protect the Ujo Tsumugi technique and quality.

Ujo Tsumugi “Color, Color, Color,”

The name “Color, Color, Color,” comes from the use of various colored yarns. When warping the warp yarns, the leftovers of previously used yarns are creatively added to give variety to the thicknesses of the stripes. When weaving, light-colored yarns and leftover weft yarns are used to create a multicolored effect. Even while producing a generally subdued impression, darker colors give accent to the design.

Masahiro Sasaki Lacquerware / Kagawa

Title of entry

Originality of expressing the intricate beauty of Kinma by gradations

Mr. Sasaki completed the Musashino Art University Graduate School of Art and Design in 1979 and was selected for the first time to the Japan Traditional Craft Exhibition in 1983. In 1990, he received the Asahi Shimbun Award at the Japan Traditional Urushi Works Exhibition (five more times thereafter) and in 2008, the Tokyo Governor’s Award at the Japan Traditional Craft Exhibition. In 2009, Mr. Sasaki was appointed as a jury member for the Japan Traditional Urushi Works Exhibition (four more times thereafter), and in the same year, he was recognized as a holder of the Kinma technique, designated an intangible cultural property of Kagawa. He was appointed as an audit committee member for the Japan Traditional Craft Exhibition in 2014 (once more thereafter), and received the Kagawa Prefecture Cultural Merit Award in 2021.

Mr. Masahiro Sasaki explores modern lacquerware while inheriting the tradition of Sanuki lacquer. The Kinma technique conventionally features a single-color base, but Mr. Sasaki introduces subtle gradations and delicate patterns that have never before been associated with Kinma. The ornate expression of his works has been highly praised by all jury members as displaying “overwhelming skills and creativity.” To further increase recognition of the technique, Mr. Sasaki has actively held group and solo exhibitions and organized workshops for primary school children for more than twenty years.

With a desire to “give originality to traditional crafts,” Mr. Sasaki has developed a gradation expression using original means based on the Kinma technique. He prepares five shades of lacquer, from vermillion to black, by adding increasing amounts of black. Vermillion lacquer is applied, followed by slightly black vermillion lacquer, then black lacquer, while shading off the border between them by applying return strokes. The lacquer is left to cure gradually in curing boxes set to three levels of humidity. Mr. Sasaki explains it is difficult to apply a thick layer of lacquer appropriate to carving a pattern in them afterward, without the lacquer dripping. After a month of curing, a checkered pattern is carved in the lacquer surface. Black lacquer is also added little by little to yellowish and reddish vermillion lacquers to prepare five different hues each. After carving the pattern, the incisions are filled with the colored lacquers. Even the same color lacquer appears differently according to the brightness of the top lacquer coating underneath. This slight variation in color creates subtle differences even with the same color of lacquer and produces a gradation. Mr. Sasaki has diversified the characteristic expression of colors of the conventional Kinma technique to produce modern Kinma lacquerware.

Dry lacquer Kinma octagonal lidded container with flower design

Black and red, considered the most beautiful colors of lacquer, are applied in a gradation on this lidded container which was crafted with the aim of creating a traditional yet new expression. The vermillion top coating of lacquer is carved according to the Kinma technique, then filled with a gradation of reddish and yellowish vermillion lacquer and polished.

Matsuzaki Doll Co., Ltd. Representative:Mitsumasa Matsuzaki * Entry as a group Edo Kimekomi dolls / Tokyo

Title of entry

Application of the Kimekomi technique to create new objects inspired by animals, insects, and plants

Mr. Matsuzaki was born in 1953 in Tokyo. He graduated from Tama Art University Department of Sculpture in 1976 and joined Matsuzaki Doll Co., Ltd. in the same year. He was appointed as president of the company in 2006 and continues to hold the post today. Mr. Matsuzaki particularly excels in wood carving and modeling, and engages in the crafting of dolls and other objects entirely with his own hands. He is a full member of Japan Kogei Association and a traditional craftsman (Edo Kimekomi dolls, Edo festival dolls).

It is said that the Kimekomi doll was first crafted around 1740 by an artisan using remnant wood after making an offertory box for a festival held at Kamigamo Shrine in Kyoto. The traditional craft is made by molding paulownia paste (paste made by mixing paulownia powder and starch) into the shape of a doll, carving grooves in the doll and tucking brocade and Yuzen fabric into the grooves using a spatula.

The technique was highly popular in crafting festival dolls, such as traditional girls’ day and boys’ day dolls, but demand for such dolls has been dwindling due to today’s aging society and declining birthrate, coupled with trends toward nuclear families and other such lifestyle changes. Koikko approaches manufacturing from the perspectives of a changing consumer awareness and a sustainable society that eschews mass production and mass consumption. It creates novel products based on new motifs and applications while retaining the warm handmade feel of the age-old Kimekomi technique, fabrics, and sense of molding, to preserve the craft and hand it down to the next generation.

insectum

The Kimekomi technique has been combined with new 3D technology to create this insect object. The intricate details are impossible to achieve by hand; they are realized by using a 3D computer. The body and legs are made by brass lost wax casting and the rest by 3D printer, and the Kimekomi was applied as the finishing touch to accentuate the beauty of the fabric and the uniqueness of its form.

Yoshinari Matsuyama Iga Kumihimo braided cords / Mie

Title of entry

Inheriting the technique of crafting Kumihimo braided cords using the soon-to-be-obsolete Karakumidai braiding stand

Mr. Matsuyama joined his family’s Kumihimo business in 1971. In 1993 he was selected for the first time to the Tokai Traditional Craft Exhibition (26 times thereafter, including four awards), and in 1996 to the Japan Traditional Craft Exhibition and the Japan Traditional Textile Arts Exhibition (20 times each thereafter, including 1 award at the textile arts exhibition). Also in 1996, Mr. Matsuyama was certified as an Iga Kumihimo traditional craftsman, and in 1998, he received a special prize at the Exhibition of Japan Traditional Craftsmen’s Association and was certified as a full member of the Japan Kogei Association. He was awarded the Mie Cultural Achievement Award in 2016 and the Sangin Furusato Culture Award in 2018.

Iga Kumihimo braided cords date back to the pre-Nara period. There are various types of braiding stands used for making Kumihimo cords, namely the Kakudai, Marudai, Ju-uchidai, Ayatakedai, Takadai, and Karakumidai. Among cords made using these stands, those made using the Karakumidai are hardly seen today, as it takes too much time and effort and poses extreme difficulty. It normally takes two weeks or so to make a complex Obi cord, but when using a Karakumidai braiding stand, it takes from two to four months and several times more effort.

The Kumihimo crafting technique using the Karakuridai has been inherited from the Heian period. After the passing of thirteenth-generation Jusuke Fukami, the sole Kumihimo craftsman who was designated a holder of an Important Intangible Cultural Property, only a small handful of people possess this technique.

Mr. Yoshinari Matsuyama is one such rare artisan who has inherited the technique, and has presented his work at the Japan Traditional Craft Exhibition. Using yarns he dyes himself, he strives to share the challenge, efforts, and splendor of the Kumihimo crafting technique using the Karakumidai braiding stand.

Kumihimo (Karakumi) “Kaleidoscope”

This Kumihimo cord is made by wrapping an 8cm × 4cm cardboard, winding five yarns together into a spool, and interlacing 112 such spools of yarn. Large diamond shapes are designed in the center surrounded by four smaller diamonds on each side within solid-color margins. Natural dyes are used to dye the yarns. Proficient skills are required to braid the cord by tightening the yarns by hand, aligning the width, and creating a smooth, flat surface. This piece took a total of roughly 140 days, six to eight hours per day, to complete.

4th MITSUI Golden Takumi Award Most Popular Award

Masao Miyamoto Kutani ware / Ishikawa

Title of entry

Handing down and preserving the tradition of mainstream Kutani ware

Mr. Miyamoto graduated from the Tokyo University of Arts Faculty of Fine Arts in 1996 and became an official member of Japan Kogei Association in 1999. In 2005, he traveled to Italy as a resident trainee under the Overseas Study Program for Upcoming Artists funded by the Agency for Cultural Affairs. He won an award at the Traditional Kutaniyaki Craft Exhibition in 2014 and was certified a traditional Kutaniyaki craftsman in 2015. His work “Green bowl with neatly aligned line design” which he presented at the Japan Traditional Craft Exhibition in 2018 and 2019 was purchased by the Imperial Household Agency. In 2021, he received the Speaker of the House of Representative Award for the “Green flower vessel Setsugetsuka” which he exhibited at the Exhibition of Japan Traditional Craftsmen’s Association.

Shinseigama Kiln was founded in 1970, specializing in the overglaze decoration of Kutani ware. Second-generation Masao Miyamoto has inherited the multicolored decoration technique of the founder, but he also pursues Ryokusai green decorations with a strict eye on color, shape, and matière, and new expressions of Aode blue Kutani ware according to an original technique. Kutani ware is characterized by ornate overglaze decorations achieved by using the five colors of Kutani known as Kutani Gosai (purple, yellow, green, dark blue, and red), but the designs have become simplified in recent years. Furthermore, there are now less and less craftsmen who can adeptly use traditional Japanese paints. With meticulous attention to the five Kutani colors, Japanese paints, and detailed drawings, and a thorough pursuit of the essence of Kutani ware, Mr. Miyamoto has sublimated traditional Kutani ware into a refined, modern craft.

As a kiln owner and chairman of the Planning Committee of the Association of Traditional Kutani Craftsmen, Mr. Miyamoto holds porcelain painting workshops and lectures, plans books, PR videos, and exhibitions, and actively engages in activities to widely introduce “authentic” Kutani ware.

Ko-gosai incense burner with bird design

Incense burner with green flower and bird design

Based on an exquisite combination of exceptionally elaborate lines and highly translucent glaze unique to the kiln, and through the repeated process of glazing and firing more than a dozen times, a stereoscopic expression appears that glows like a jewel. A single refined line becomes a pattern, and these patterns assemble to form a picture. It is the quintessence of Shinseigama Kiln born of ceaseless pursuit down to the smallest detail.